Problems: New fittings such as depth/speed log and chirp transducers will require a more durable epoxy resin applied. The parts are best fit before copper coating to my thinking. Let’s see....

|

With osmosis treatment applied and dried after a 6 months standard drying time. The epoxy resin can be reapplied to protect the repaired naked fibreglass. This is one of three types of resin. It’s best suited for covering the hull. 5 coats are being applied here, after which the copper coating will bling bronze to gaurd from electro magnetism which would cause earlier regrowth of the osmosis.

Problems: New fittings such as depth/speed log and chirp transducers will require a more durable epoxy resin applied. The parts are best fit before copper coating to my thinking. Let’s see....

0 Comments

To do commercial business on the Mediterranean you need a few things. Not a few cameras; you need an endorsed licence , a certified commercial registered vessel and the go ahead from the country authorities of the waters you’re doing business in.

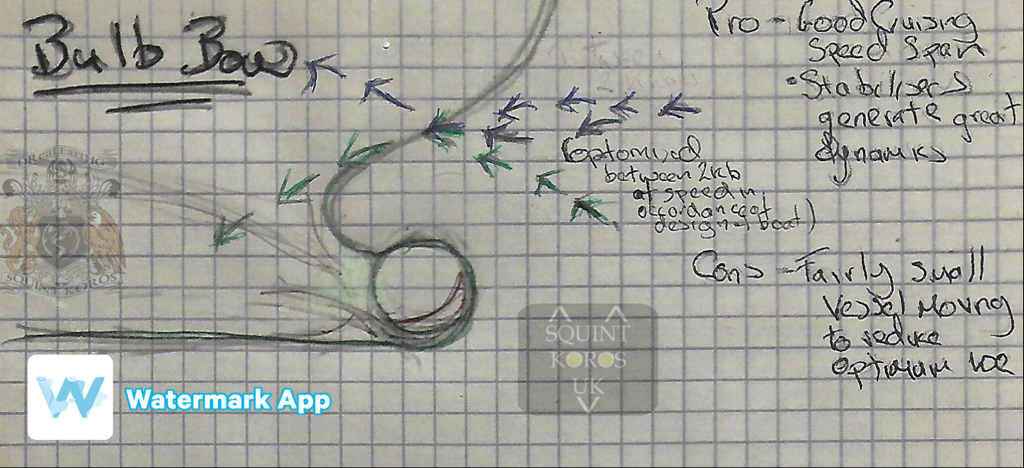

Not to worry, because for the clear sight of these criteria to appear, TandEadapt, has a few cameras. The first camera is on the stern of the vessel and is already installed, working with the Garmin Marine Navigation Network on board. The next two cameras which have just arrived are to be placed on the starboard and port, at angles of the end of mast lights 225 degrees and Nav lights 112.5 degrees for servailance of Starboard and Port, Bow. They will be mounted upon the fly bridge sides for high viewing and discretion. This along with the stern camera will provide a flexible panaramic of viewing what is occurring outside the vessel. Where the cameras are not at angles to record, the vessel can be manoeuvred to compensate in an instance. The dates of fitting are unknown but it won’t be before the completion of the structural rebuilding planned in August and September are complete. Future fittings may include a bow camera, however with hand held devices and other recording devices; from the bridge or fly bridge, it is not essentially needed at this time. The Bulbous Bow is the final addition being constructucted to improve the stability of the trawler on water. The shape and hydrodynamics are to redirect the current of the water to grip the bow on its course. If correctly navigated and steered, the trawler will hold itself at a cruising speed without rolling or rocking in swells and waves the way it did before.

This addition is custom designed and not practically used on a semi displacement vessel of this type. It would be argued the bulb bow would be innefective due to the light weight and smaller size of the vessel, which would be rocked and rolled anyway. However, this has been designed to work in coilition with the added keels and fins at the base of the centre starboard and port of the ship. This enhances the hydrodynamics of the hull to properly utilise a bulb bow here. That being said, as the diagram below will show, this addition can only have full affect between two knots of the trawlers speeds. With this particular trawler, capable of 20 knots, I can guess it will be at an optimum cruising speed between 12 and 14 knots. A proper sea trial is required before an actual optimum speed can be quoted. The barnacles and remaining deposits which covered parts of the trawlers external mechanical manouvering components, were cleared before the final repainting and propeller shaft guards attached.

The hull will have a copper coating, that is a better coat than normal gel coat, for preventing the magnetic fields of the water and instruments causing rapid regrowing and deteriorating problems like, Osmosis and corrosion under external fittings. The inox shaft and propeller guards will then be fitted to support them on shore landings. Stones and sand could otherwise damaged the propellers, also the shafts could otherwise be buckled under the strain of a mis balanced shore landing. |

AuthorAaron Dia Pemberton. RYA qualified skipper. Trawler yacht captain of T&Eadapt Categories |

RSS Feed

RSS Feed